Why choose copper foil material for RF/MRI Room Installation?

Copper is durable, has superior electrical conductivity and is extremely corrosion resistant. Copper is also easily formed meaning that the shape of the shield can be easily modified to suit rooms of different shapes and sizes.

2. Reinforced wall design

3. Lightweight

4. Installed in more MRI sites worldwide than any other shield system

5. Can be easily and quickly modified on site should a problem or change occur

6. Copper serves as an eddy current shield for EMI protection

|

Shielding ED Copper Foil Characteristics |

||||||

|

Quality Items |

General Technical Terms |

|||||

|

2oz |

3oz |

4oz |

5oz |

6oz |

||

|

Area Weight(g/m2) |

70um |

105um |

140um |

175um |

210um |

|

|

610±30 |

915±45 |

1220±60 |

1525±75 |

1830±90 |

||

|

Tensile Strength(kg/mm2) |

Room Temperature |

≥25 |

||||

|

Elongation (%) |

Room Temperature |

≥5 |

||||

|

Pinhole, Leakage Points |

no |

|||||

|

Quality Resistivity(Ω.g/m2) |

≤0.162 |

|||||

|

Oxidation Resistance(160℃/30min) |

No Oxidation and Discoloration |

|||||

|

Width |

1320-1370(±1.0mm) |

|||||

|

Surface Quality |

No Contaminant and impurity |

|||||

|

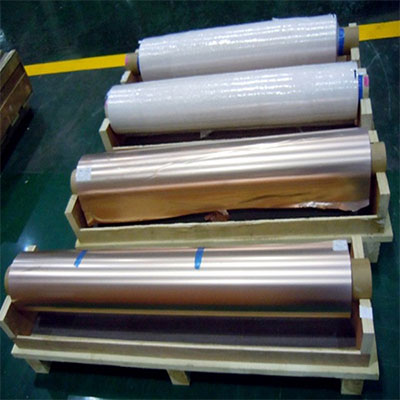

Shape |

In Roll |

|||||

|

Heavy Shielding ED Copper Foil Characteristics |

|||||

|

Quality Items |

General Technical Terms |

||||

|

6oz |

8oz |

10oz |

12oz |

||

|

210um |

280um |

350um |

420um |

||

|

Area Weight(g/m2) |

1930±90 |

2440±120 |

3050±150 |

3660±180 |

|

|

Tensile Strength(kg/mm2) |

Room Temperature |

≥28 |

≥28 |

≥28 |

≥28 |

|

High Temperature 180℃ |

≥20 |

≥20 |

≥20 |

≥20 |

|

|

Elongation(%) |

Room Temperature |

≥10 |

≥10 |

≥20 |

≥20 |

|

High Temperature 180℃ |

≥5 |

≥5 |

≥10 |

≥10 |

|

|

Surface Roughness (um) |

Room Temperature |

≤0.43 |

≤0.43 |

≤0.43 |

≤0.43 |

|

High Temperature 180℃ |

≤5.1 |

≤5.1 |

≤5.1 |

≤5.1 |

|

|

Peel Strength(Kg/cm) |

≥1.1 |

≥1.2 |

≥1.2 |

≥1.2 |

|

|

High Temperature Anti-Oxidization Performance(180℃/h) |

No Oxidation and Discoloration(Treat in the 180℃ |

||||

|

Shape |

In Sheet |

||||

|

Surface Quality |

Uniform Color, no copper blotch and contamination,smooth shearing area, and no shear power or shear mark |

||||